Machinery

COM-CNC – Spring Coilers

(7 Products)

- Designed for production of compression, extension, conical (one or both sides) springs and rings

- Servo Driven Axes

- 2-Coiling Point System

- Cam-less direct drive and control for right and left coiled springs

- New Real Spring software enables fast and easy machine programing

- Available SCPC Camera spring gauge measuring system

COM-20 CNC

WIM-CNC – Lathe Coilers

(7 Products)

- Automatic servo controlled for COLD production of right and left coiled cylindrical, one side conical compression, extension and torsion springs, different wire forms and double torsion springs

- Available with up to 5 controlled axes

- Available wire catching system (WCS) for 1st coil

- Available graphical SpringMaster software SM4

WIM-20 CNC

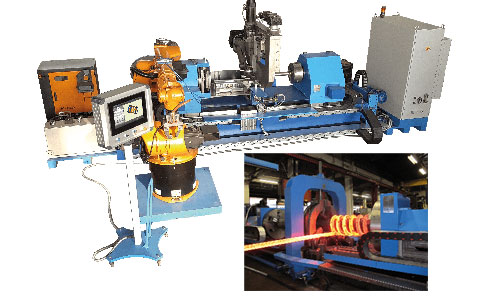

WIM-H-CNC – Lathe Coilers for Hot Coiling

(1 Product)

- Servo controlled Lathe Coiler

- Custom made to customer specifications up to 100mm wire diameter

- Specify wire materials (CrSi, CrV4, W.Nr. 1.4310, EN 10270, Tungsten, etc.

- Specify wire diameter, spring OD range and length, bar or coil, minimum length of spring leg, right and/or left coiling and level of automatization (robotic bar feed, spring removal, etc.)

- Available graphical SpringMaster software SM4

WIM-H-CNC

DTL – Fully Automatic Double Torsion Springs

(1 Product)

- This machine is designed for a robot supported production of double torsion springs

- 3D SpringDesigner software makes programming easy

- Production line with one coiling station can produce up to 200 pieces/hour; two coiling stations can produce up to 400 pieces/hour

DTL-R-CNC

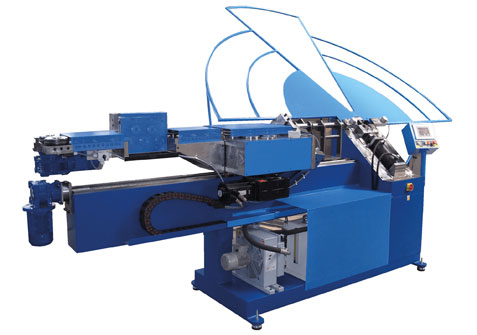

LTD – The LTD CNC line consists of two types of machines to produce Double Torsion Springs

(4 Products)

-

LTD OBL

Machines produce U-forms

- Servo controlled machine straightens wire from wire coil

- Then produces the U-form for making double torsion springs

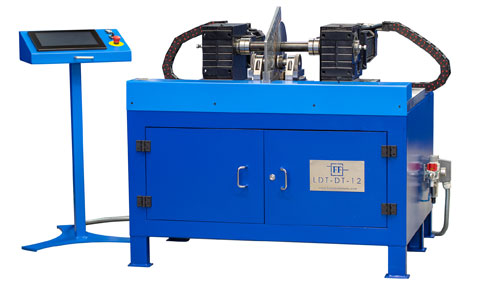

-

LTD DT

Machines coils U-forms into Double Torsion Springs

- Servo controlled machine is used for coiling Double Torsion Springs

- Using the U-forms that are produced on the LTD OBL machine, the LTD DT machine will coil Double Torsions Springs

LTD-OBL-12

LTD-DT-12

BEM-CNC – Table Wire Benders

(4 Products)

- Servo controlled semi-automatic wire forming machines are designed for fast and easy production for bending wire and strips

BEM-20

GRM-CNC – Spring End Grinders

(4 Products)

- Servo controlled semi-automatic spring end grinder machines are used for horizontal crush or down-feed grinding

- Automatic height adjustment in coordination with the number of revolutions of the grinding wheel increases capacity and efficiency

- Programmable control technology for loading table simplifies the loading of the machine

- Automatic unloading and semi-automatic compensation of the grinding wheel wear increases productivity

- HMI CNC control unit makes set up and operation easy to use

GRM-16

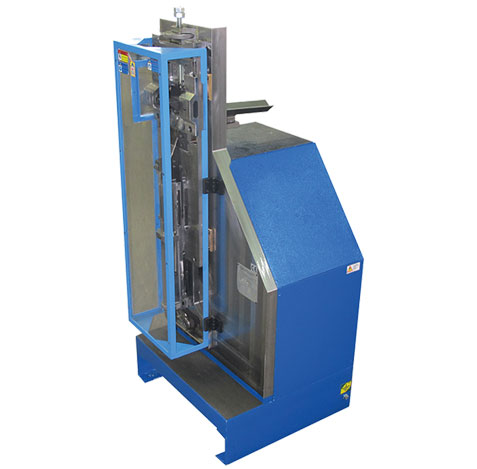

OBW – Spring Loopers

(3 Products)

- Semi-automatic looping machines are designed to produce loops on pre-coiled extension springs

- EN 10270-1 DH / ASTM A228 Wire diameter from 0.8 mm to 8 mm

- Spring OD from 5 mm to 90 mm

OBW-8

MPK – Heavy Spring Loopers

(3 Products)

- Semi-automatic hydraulic driven spring looping machines are designed to produce loops on pre-coiled extension springs

- EN 10270-1 DH / ASTM A228 Wire diameter from 5 mm to 20 mm

- Spring OD from 25 mm to 240 mm

- Tooling for CrSi wire available

MPK-20

CMH – Trimmers

(4 Products)

- Semi-automatic trimming machines are designed for cutting off the springs, spring ends and spring legs

- Equipped with special hydraulic system for faster and more effective cutting

- Stroke adjustment for small wire sizes increases productivity

CMH-35

HMV- Power Reels

(8 Products)

- Electric power reels with a load capacity up to 2400 kg

- Right- or left-hand power reels

- 2-speed and brake adjustable by potentiometer

- Asynchronous or brushless motors, fan cooled

- Emergency switch for the machine stop with audible alarm

- The dance is equipped with wire guide, counterweight and adjustable spring tension

- Baskets for reels for use of oil tempered wire are available

HMV-2000